You may have seen them.

You may own them;

Those pieces that look like wood, but feel and even smell like Bakelite.

Maybe you have heard that they are Bakelite treated to look like wood..

Well, I have done a lot of research into what exactly they are. The answer is.....

BOTH!

BOTH!

They are wood that has either been impregnated with Phenolic resinoid and laminated, or that has been just laminated with it.

In a career in antique furniture reproduction and helping to build a wooden Yacht form the keel up, I had learned a lot about woods, and about treated woods. That sparked a curiosity about impregnated woods back in the early 1990s. I was fascinated with airplane propellers that were as hard and smooth as stone, and laminates that were smooth all the way through, even when cut.

At that time, I was interested in Bakelite, and had a few pieces, but never put the two together, per se.

With the woodworking experience, I knew how to research, and what to look for to get my answers about the collection of about 50 pieces of Wood/ Bakelite laminates I have.

If you have read about the history of Bakelite, you may remember that the first viable formula was wood soaked in the formula. Mr. Baekeland tried it because the first formula was too brittle.

I will let the books I have on the subject tell the story of Phenolic wood laminates. This information is comprised from books I own from 1939, 1941, 1942, 1945, 1946, and 1948, and will be in quotes.

|

| Yeah.. they used to use BLOOD! Now, we can say that Phenolics are humane! |

"Plywood is built up of layers or thin slices of wood called veneers, glued together with the grains alternating at right angles. The layers of this type of plywood generally separate when exposed to moisture.

The

difference between a plastic laminate an an ordinary plywood is that the

core material (wood veneers, paper, linen, etc..) is impregnated with

resin so that this is continuous right through, not just a glue line. Several

companies now manufacture a synthetic resin adhesive which is used in

the bonding of plywood. The most common resin adhesives for bonding of

plywood are the Phenol-Formaldehyde and the Urea-Formaldehyde adhesives.

In the manufacture of

laminated sheets, the base layers are first saturated with a liquid

resinoid, or they may be sprayed with a resinoid surface coating."

"Once

the sheets have been impregnated, they are arranged in stacks of the necessary size to produce sheets of the desired thickness."

|

| Dresser most likely finished in Mahogany. |

"Poplar, Birch,

and Spruce, Avodire, Maple, Walnut veneers, low in natural resin content

are being employed in the development of resin bonded structures. In

some outside facings, Mahogany veneers are employed for hardness. Thickness of veneers range from 1/48" to 1/8". "

"Laminated

Plastics is made from superimposed layers of fibrous or porous sheets

coated or impregnated with resinoid and becomes a solid mass by the

application of heat and pressure in a large hydraulic press. Up to 8X20

feet Heat is usually applied through steam platens on the top and bottom

and top of the stack, but sometimes dielectric heat is used. A typical

press may produce sheets 3' X 8' in size and a variety of thickness

varying from 1/16" to 1" or more in thickness. A total pressure of over 5

million pounds may be exerted by the press. Laminated

plastics forms have an advantage over the other plastic forms in that

they receive the benefit of mechanical reinforcement from the

laminations; then, too, they possess the insoluble and infusible

properties of the resinoid binder. By varying the process of

manufacture, a laminated sheet may have the appearance of the non

plastic layer, (such as wood or canvas). They serve to

broaden the scope of plastics in the styling of numerous machines and

accessories. They are easily kept clean and maintain a permanence of

finish that exceeds even the qualities of other surface coating

materials.

In 1926, Dr.

Goldschmidt developed the Tego process for manufacturing plywood

articles. Practical

commercial bonding of plywood with synthetic resins began with the

introduction in this country (USA) of a Phenol- Formaldehyde resin in sheet

form, first manufactured in this country in 1935 after several years of

successful service abroad. In 1941, the Forest Products Laboratory of the U.S. Department

of Agriculture, located at Madison Wisconsin, was given a million

dollar grant for research on wood products. Net result: two new kinds of

plywood material, impregnated wood, called Impreg, and compregnated

wood, called Compreg. Impreg is plywood that has been given a bath in

resin under pressure which forces the resin into the wood cells where it

enters into a molecular alliance with the molecules themselves. Compreg

is also given a bath under pressure, but the pressure is stepped up to

250 pounds per square inch. The American Compreg is made by applying the

resin in the Phenol-alcohol stage of condensation and the smaller, more

highly polar molecules penetrate into the cell walls of the wood. The

result is substantially a new material- neither a plastic or a wood, but

with the beauty of the wood's grain and texture, yet possessing the

fire, heat, moisture, and bacterial-resisting virtues of a phenolic

plastic."

"Pregwood is

another Formica developement with great possibilities. This is a product

in which laminations of actual wood are impregnated with Phenolic

resins and pressed into solid sheets. This tough material has also been

used for Military skis. Phenolic plywood resins were turned out at an

annual rate of about 36,000,000 pounds. This was used to make

approximately 600,000,000 square feet of 3 ply material use in boats,

hutments, decking, gliders, and power aircraft, etc..

One of the

strongest plastics products is Pregwood, an impregnated wood. Pregwood

has a tensile strength of 30,000lb. per sq. inch. Pregwood actually

shows up better on this basis than chrome- molybdenum steel with 22,900,

or Aluminum alloy, at 22,100."

| ||

| More Phenolic plastics were made for this purpose than any other. |

"Production of all plastics materials in 1944, according to the War Production Board, was about 800,000,000 pounds. of this, over 400.000.000 pounds was in structural or rigid plastics.

Resins for the paint, varnish, and lacquer industry; this is probably the largest single outlet for the plastics industry."

When polymerizing the laminate formulas, they are completely hardened. This is different than Jewelry grade Phenolics, which are not completely polymerized because they would be too brittle. Bakelite that has seen a lot of heat cracks and breaks easily. That is why a lot of flatware is split at the point where the metal shank was inserted.

|

| "Complete house, inside and out, is constructed of Resnprest Durez bonded plywood. Note the smooth rounded surfaces" |

"Of course, only thermoplastic materials have value as scrap, since they can be melted down, and used again, whereas the thermosetting materials have no further value after once being used. However, scrap materials will doubtless continue to be made and sold for technically unimportant parts or consumer goods.

Like most processes, laminating is most economical when done on a large scale."

I believe that most of the laminated Phenolic jewelry was made from scrap, since it was never mentioned other than as a "novelty" in the many books I've read about phenolics.

|

| Belt made from Phenolic impregnated wood. |

|

| Earrings made from "Bakelite" impregnated, laminated wood. |

|

| Bakelite laminated Mahogany brooch. |

|

| Mid Century Modern Brooch of Phenolic laminated woods and Lucite. |

Many planes were made with Resin bonded wood, mostly Spruce. This is how the "Spruce Goose" got it's derisive nickname by the media, although it is made mostly of Birch.

|

| Timm Aircraft training plane built of phenolic resinoid bonded plywood. |

If someone in your family flew for the Military in WWII, they most likely had been in, or flew a Bakelite plane!

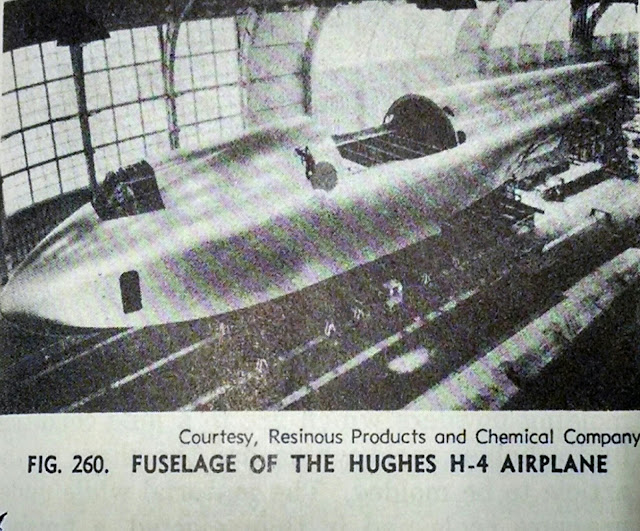

"One of the most unusual applications of the resin bonded plywood is in the construction of the Hughes H-4 airplane."

|

| The largest piece of Bakelite in the world! |

I was extremely lucky to have been able to talk with one of the engineers that was in charge of the lamination of the Hughes H4 "Hercules" at the Evergreen Aviation Museum in McMinnville Oregon. I was dressed in all 1940s, suit, tie and hat, which usually makes it easier to talk with museum administrators. ;-)

You bet I rubbed and smelled the plane! Unfortunately, it didn't test positive because of the paint.

I did smell his sample piece of laminate that was bent in an L shape. He thought I was weird, and didn't really get what I was saying about jewelry and such made of Phenolics.

"Duramold is a composite material process developed by Virginius E.

Clark. Birch plies are impregnated with phenolic resin, such as

Haskelite and laminated together in a mould under heat (280°F) and

pressure for use as a lightweight structural material. Similar to

plywood, Duramold and other lightweight composite materials were

considered critical during periods of material shortage in World War II,

replacing scarce materials like aluminum alloys and steel." - Evergreen Aviation Youtube video of the H4.

As a side note; the Engineer I spoke to was the fourth person to know that this plane was going to fly. Howard Hughes didn't tell anyone so that there would be no chance of stopping him. As they were taxiing across the water, the engineer was in the tail of the plane with the operator of that section. At that time, they didn't have the technology to physically connect the cockpit controls all the way to the tail of the plane, so he had to radio a man and tell him how to move the rudder and elevators.

When he gave the signal to set the elevators at a certain angle, he turned to the engineer and said "Hang on. We are going to fly!".

It makes perfect sense that people saw the beauty in the scrap, just as they did with the overspray that built up from painting cars, and made jewelry from it.

I love my job, and enjoy digging up these little to unknown facts about Phenolic resiniod jewelry!

For more fine examples of these and other Bakelite jewelry check this out!

Thank you for reading and supporting my love of this material!